Block machine featuring high production efficiency, easy and effortless to operate: the operator can work almost always sitting at the control levers. The excellent quality of compression together with a fast production cycle ensures a smooth, evenly crafted and considerable output of concrete blocks. Electric panel and updated controls give improved safety and steady performance; also easier to maintain and service due to components being standard and worldwide available.

Mechanical parts and hydraulic elements exceeding necessities guarantee long life and extreme reliability. Quality production, minimum service and maintenance needs together with rugged, strong built make it the safe choice for the most demanding producers.

TECHNICAL FEATURES

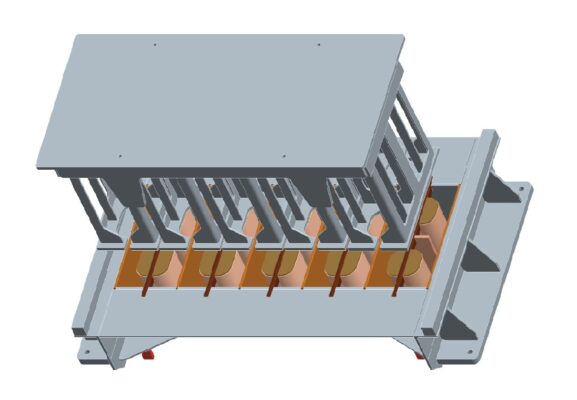

- Egg-laying semiautomatic block machine with bucket loading

- Manual steering

- Double horizontal side vibration

- High impact weight compression

- Hydraulic delivery complete with torsion bar

- Mould size: cm 126 x 50 x min 20 cm max 25 cm

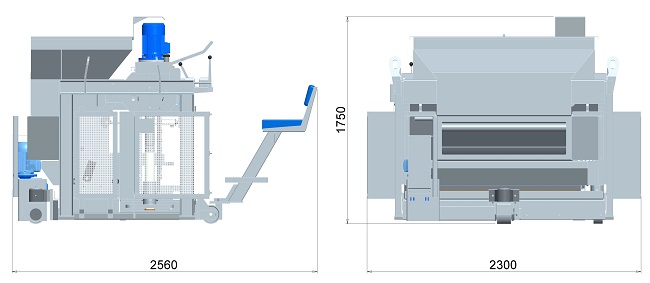

- Machine size: cm 256 x 230 x h175 – Weight kg 2.200

- Motors and power: 4 motors tot. 8,6 Hp (6,3 kW)

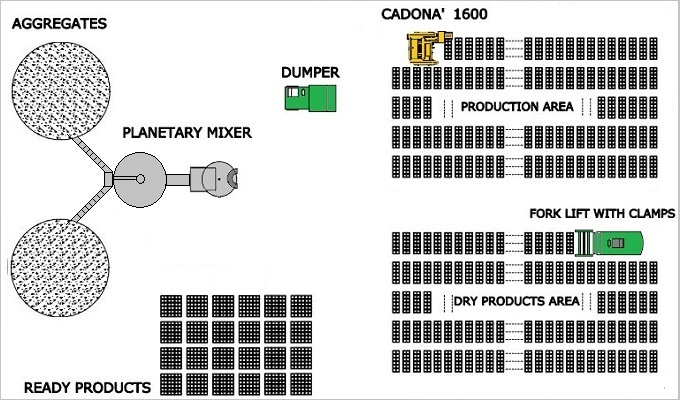

- Space required for one day of production and drying: 2.000 sq/m

- Ancillary equipment needed: planetary mixer 10 m3/h + dumper or forklift with tilting bucket

Hourly production

130

cycles per hour

NO PAVERS

750

(20x40x20cm)

Blocks per mould

20x40x20: 6 pcs

15x40x20: 8 pcs

10x40x20: 12 pcs

350

(100 cm)

Kerbs per mould

12/15x100x25: 3 pcs

Hourly production

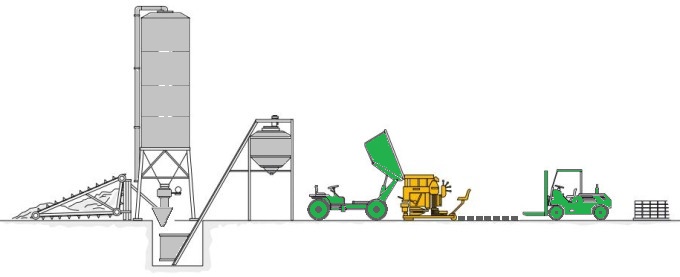

Plant example

To complete the plant you will need: planetary mixer 10 m3/h+ dumper or forklift with tilting bucket

More info

Dimensions of machine ready to work: cm 256 x 230 x 175

Box for shipment: 230x230x200