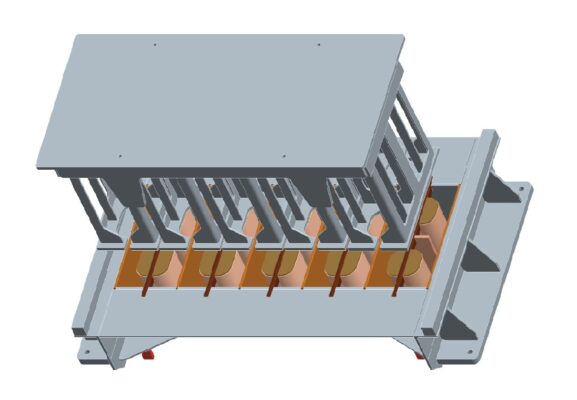

A new concept for a mobile block machine that has been designed to add the production of pavers alongside usual high quality production of blocks and kerbstones. To that end the machine is provided with double (side and top) vibration and can easily vary the height of production. Reliability is guaranteed since this machine stems from the time tested 1000A6. The mould is slightly smaller to allow an even vibration and a better compression to result in a good quality production of pavers and any solid concrete product.

Easy and effortless to operate M150 is the ideal entry-level compromise machine for a small business who is willing to start out with maximum versatility and minimum equipment.

TECHNICAL FEATURES

- Egg-laying semiautomatic block machine with manual loading

- Front and upper circular horizontal vibration with automatic stop

- High impact weight compression; extra vibration on press.

- Hydraulic delivery with torsion bar; press is hydraulically lifted

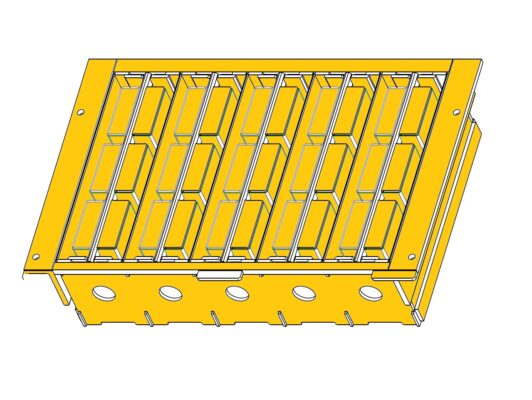

- Mould size: cm 108 x 52 Height: Min 5 – Max 30 cm

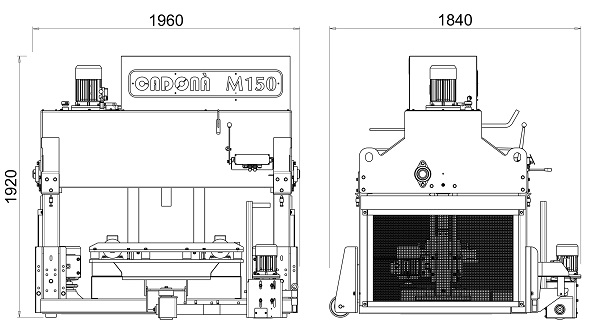

- Machine size: cm 184 x 196 x h192 – weight kg 1.900

- 6 motors total power Hp 9,9 (kW 7,3)

- Space required for one day (8 hours) of production and drying: 1.200 sq.mt

- Ancillary equipment needed: planetary mixer 6 m3/hour + high capacity wheelbarrow

Hourly production

80

cycles per hour

35

m2 (square meter)

Pavers per mould

20X10: 25 pcs

400

(20x40x20cm)

Blocks per mould

20x40x20: 5 pcs

15x40x20: 7 pcs

10x40x20: 10 pcs

140

(100 cm)

Kerbs per mould

12/15x100x25: 3 pcs

Hourly production

Plant example