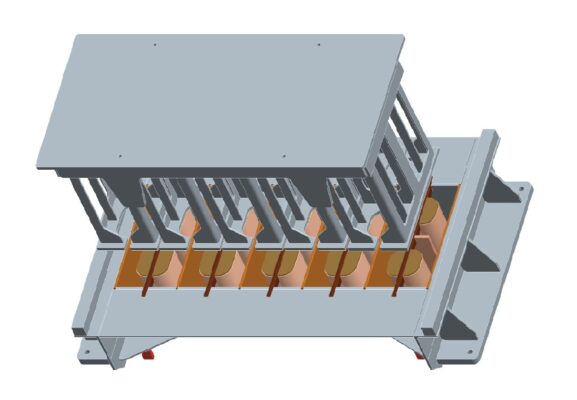

Simple, rugged and productive block machine requiring a mimimum plant. It works with the same mould of 842 Hydraulic, but thanks to its improved hydraulic system M515 decidedly improves the final quality of concrete output. The block machine is very easy to operate and needs minimum service. Mechanical parts and hydraulic elements exceeding necessities guarantee long life and extreme reliability.

M515 has always been the best choice to produce solid blocks and kerbstones; the update version can also produce pavers making it the most versatile machine of its size.

TECHNICAL FEATURES

- Egg-laying semiautomatic block machine with manual loading

- Front circular horizontal vibration with automatic stop

- High impact spring compression: great force for an easy and fast delivery of blocks

- Hydraulic delivery complete with torsion bar; press is automatically blocked and lifted

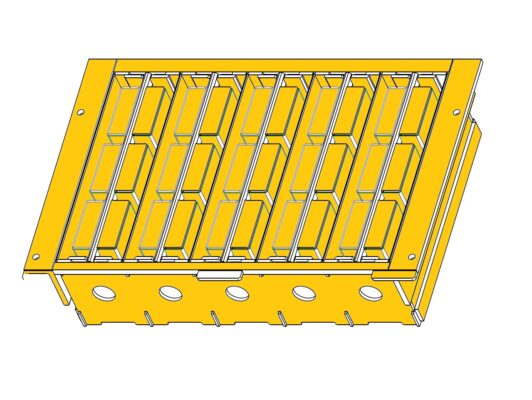

- Mould size: cm 80 x 50 Height: 20 cm

- Machine size: cm 130 x 140 x h175 – Weight kg 730

- 3 motors total power Hp 4,3 (kW 3,2)

- Space required for one day of production and drying: 800 sq.mt

- Ancillary equipment needed: drum or planetary mixer 5 mc/hour + wheelbarrows

Hourly production

70

cycles per hour

25

m2 (square meter)

Pavers per mould

20X10: 14 pcs

280

(20x40x20cm)

Blocks per mould

20x40x20: 4 pcs

15x40x20: 5 pcs

10x40x20: 7 pcs

100

(50 cm)

Kerbs per mould

12/15x50x25: 2 pcs

Hourly production

Plant example

More info

Dimensions of machine packed for shipment: cm 135 x 140 x 180