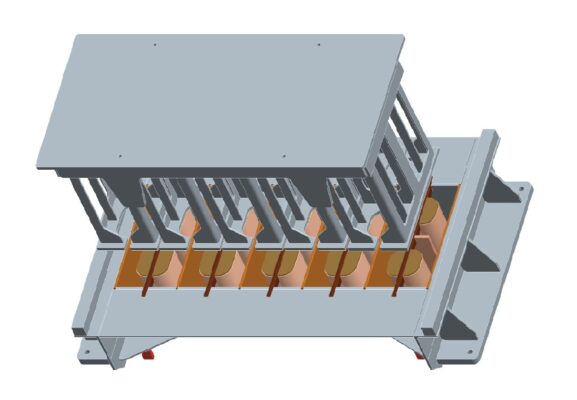

Semiautomatic block making machine with accessory device for the finishing top layer (RD version). Reliable, sturdy, fast (140-180 cycles per hour) semiautomatic and featuring brand new patented technological solutions, Cadonà 1053 has a great value for money appeal.

SR1053 is the natural evolution of clients’ favourite S1010: it’s faster, more automatic and productive, but always user-friendly. The operator is only necessary to provide his expertise on controls. The RD1053 version implements double layer paver production.

TECHNICAL FEATURES

- Semiautomatic stationary block machine – bucket loading – automatic pallet feeding – elevator

- Hopper capacity: 650 lt. (+ 50 lt RD version)

- Automatic pallet loading and movement

- One-way vertical vibrator with adjustable speed

- Adjustable vibration depending on production output – extra vibration on press

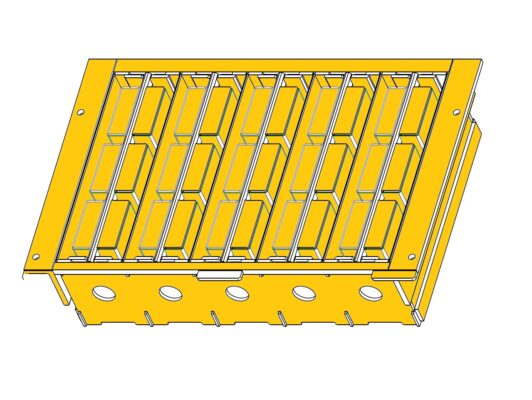

- Mould size: cm 108 x 52 Height min. cm 4 max. 30

- Machine size: cm 700 x 300 x h360 – weight kg 6.400

- Motors and power: 5 motors Hp 12.75 (kW17)

- Pallets size: cm 115 x 58 x 4

- Pallets per shift (8 hours): 1.200 pcs

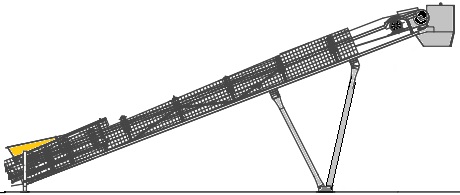

- Ancillary equipment needed: planetary mixer 500 lt. + conveyor belt + pallet

Hourly production

150

cycles per hour

75

m2 (square meter)

Pavers per mould

20X10: 25 pcs

700

(20x40x20cm)

Blocks per mould

20x40x20: 5 pcs

15x40x20: 7 pcs

10x40x20: 10 pcs

290

(100 cm)

Kerbs per mould

12/15x100x25: 3 pcs

12/15x50x25: 6 pcs

Hourly production

100

cycles per hour

50

m2 (square meter)

(Double layer)

Plant example

Advantages of having two machines instead of a bigger one

Cadonà production choices are rooted in a simple observation: fully automated plants have been created to reduce manpower: the higher costs needed to both buy and maintain those fully automated plants are to be retrieved thanks to the cut in labour costs. This plan make sense in countries where manpower is very expensive, everywhere else it’s more logical to keep the initial capital expenditure as low as possible. Even more so where bank rates are very high and wages are relatively low.

Cadonà block machines have been designed to target those needs. The production quality is as high as in bigger machines while installation and maintenance are much simpler so they can be made by local mechanics. The total cost of two machines is still lower than a big automatic one of comparable productivity and quality. And there’s no need for technical training: our machines can be operated by non-specialized personnel.

Other advantages of having two machines instead of one:

- Smaller pallets are much easier to handle and move.

- With a smaller mould size the cost of pallets and moulds is considerably lower so it is also much cheaper to offer a wide range of products for your customers.

- When two identical machines use the same moulds, for the best selling products it’s possible to have two identical moulds at work simultaneously. Otherwise you can diversify.

- More flexible production. If one machine is on halt for maintenance the other one will still work.

- When the market request is low only one machine is working, lowering the cost.

- The power consumption is optimized, the whole plant here presented needs about 50 Kw.

More info

The machine fits in a 40′ open top container – minimal operations required for the set up of the plant